Plastic Manufacturing Can Be Fun For Anyones

Wiki Article

What Does Oem Do?

Table of ContentsHow Lean Production can Save You Time, Stress, and Money.The 6-Second Trick For OemUnknown Facts About Lean ProductionPlastic Manufacturing for DummiesHow Lean Manufacturing can Save You Time, Stress, and Money.Lean Production for Dummies

The text on this page is a sample from our full White Paper 'Shot Moulding for Purchasers' - * Example text * - for complete overview click the download button over! Introduction This guide is intended for individuals that are aiming to source plastic mouldings. It gives a much needed understanding right into all that is involved with producing plastic parts, from the mould device needed to the moulding process itself.If you want to explore better, the guide covers types of mould tools, along with unique finishing procedures such as colours & plating. Words that are underlined can be located in the glossary in the appendix ... Component I: Moulding: The Essentials The Advantages of Shot Moulding Plastic shot moulding is an extremely precise procedure that offers numerous advantages over other plastic handling techniques.

Accuracy is excellent for extremely complex components. Compared to various other strategies, moulding enables you to incorporate more functions at extremely tiny tolerances. Have a look at the photo to the. You can hold this moulding in the palm of your hand and it has managers, ribs, steel inserts, side cores and openings, made with a gliding shut down feature in the mould tool.

The Of Manufacturing

The Facts About Die Casting Revealed

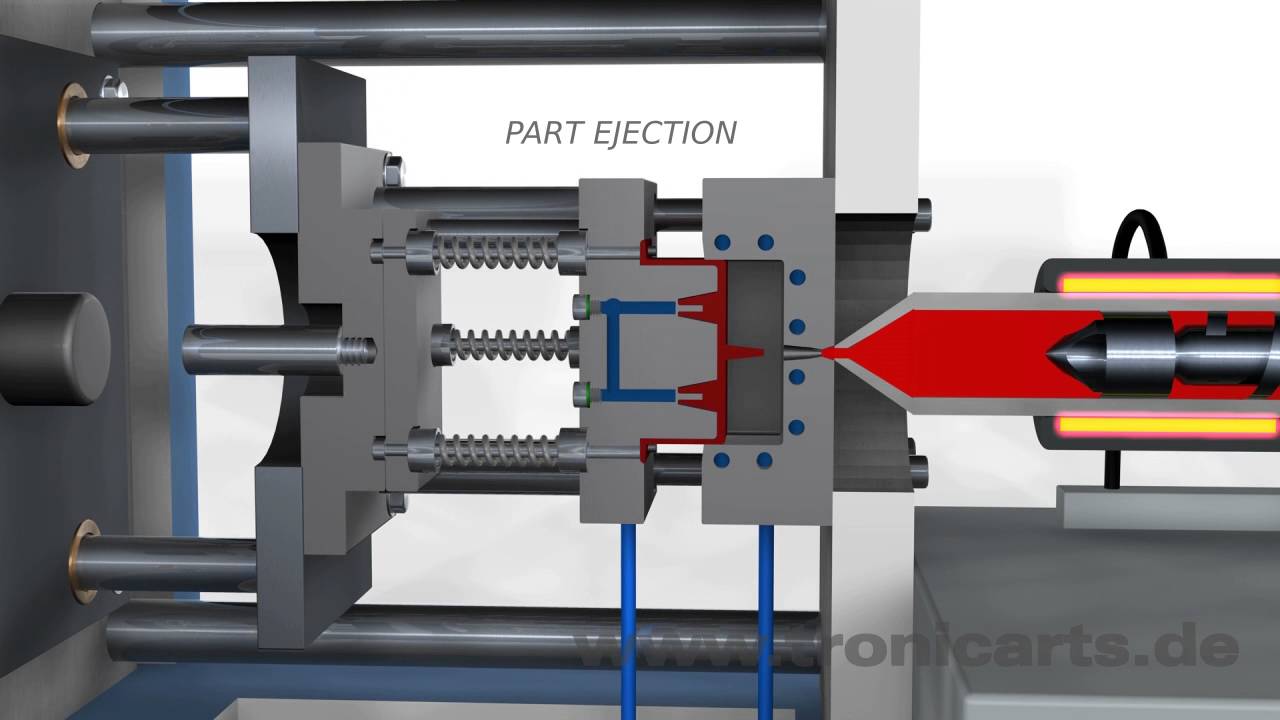

from material feed Product melting; material injection; cooling time cooling down ejection and also the re-closing of the mould tool ready for prepared next cycle. Draft angles - The walls of a moulded part should be somewhat tapered in the instructions in which the component is ejected from the mould device, to permit the component to be expelled quickly.Ejector stroke - The pushing out of ejector pins to eject the moulded component from the mould device. Ejector stroke speed, length and also timing needs to be very carefully regulated to prevent damages to the ejectors and also mould device, however at the very same time make the moulding cycle as brief as feasible.

The Main Principles Of Manufacturing

Ribs - When a plastic part has slim walls, ribs are included in the style to make the slim wall surfaces more powerful Side cores - Side activity which produces a feature on a moulded component, at an opposing angle to the typical opening direction of the mould tool. manufacturing industries. The side core needs to be able to retract as the plastic component can not be ejected otherwise.

Wall surfaces - The sides of a moulded part The message on this web page is an example from our complete White Paper 'Injection Moulding for Buyers'.

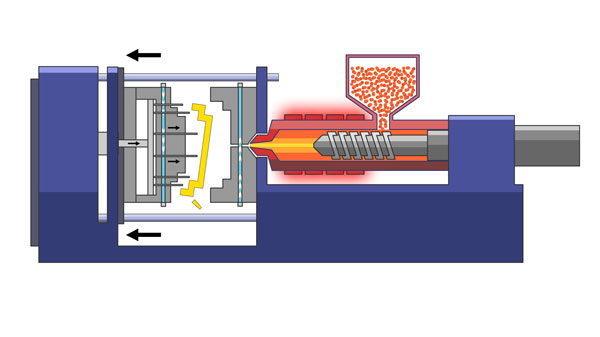

Shot moulding is commonly utilized for producing a variety of parts, from the tiniest components to whole body panels of cars and trucks. Developments in 3D printing innovation, using photopolymers that do not melt during the injection moulding of some lower-temperature thermoplastics, can be made use of for some basic shot moulds. Injection moulding makes use of a special-purpose equipment that has three components: the injection device, the mould and also the clamp.

The smart Trick of Oem That Nobody is Talking About

Process attributes [modify] Shot moulding makes use of a ram or screw-type bettor to compel molten plastic or rubber material into a mould dental caries; this solidifies into a form that has complied with the contour of the mould. It is most frequently utilized to refine both polycarbonate and also thermosetting polymers, with the quantity use the previous being considerably higher.: 13 Thermoplastics are widespread because of features that make them highly suitable for shot moulding, such as simplicity of recycling, versatility for a broad range of applications,: 89 and capability to soften and stream on home heating.In multiple dental caries moulds, each tooth cavity can be identical and also develop the same components or can be special and form numerous different geometries throughout a single cycle.

The screw delivers the raw material ahead, mixes and also homogenises the thermal and also viscous distributions of the polymer, and also decreases the required heating time by mechanically shearing the material and also adding a considerable quantity of frictional home heating to the polymer. The product feeds ahead with a check valve and also collects at the front of the screw right into a quantity referred to as a shot. When sufficient product has gathered, the material is compelled at high pressure as well as rate into the component creating dental anonymous caries. The precise amount of contraction is a function of the resin being utilized, as well as can be relatively foreseeable. To avoid spikes in stress, the procedure normally makes use of a transfer setting representing a 9598% complete dental caries where the screw shifts from a consistent rate to a constant stress control.

The Best Guide To Mfg

The packaging pressure is applied until the entrance (dental caries entryway) strengthens. Due to its little dimension, the entrance is generally the first place to solidify via its entire thickness.: 16 Once the gateway strengthens, no even more material can go into the cavity; appropriately, the screw reciprocates and also acquires material for the next cycle while the product within the mould cools down so that it can be expelled and be dimensionally stable.Report this wiki page